Producing metal and plastic prototypes with the CEM process

A new generation of 3D printers: ExAM 255

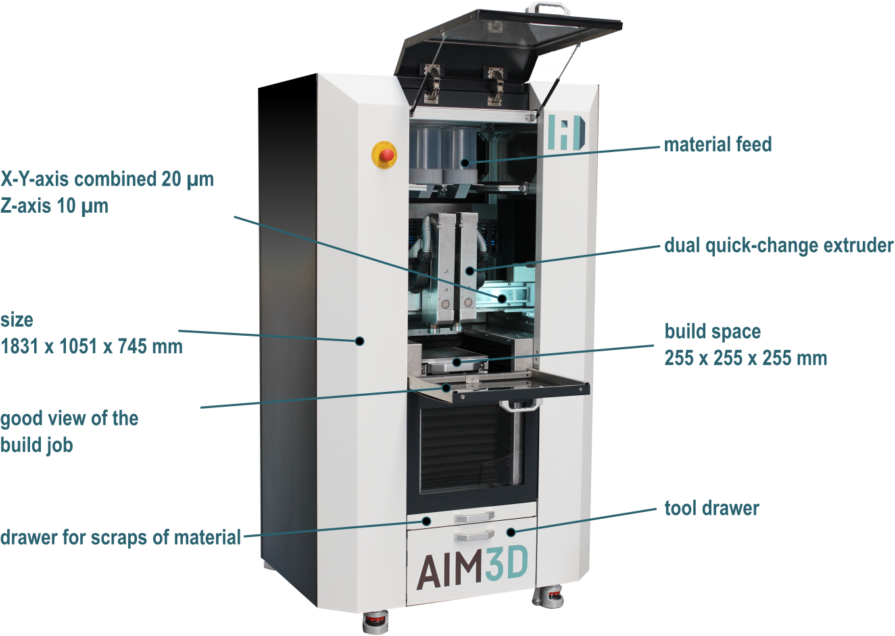

The ExAM 255 is the world’s first industrial 3D printer to process injection moulding pellets. The production of metal components with the innovative CEM process is cost-efficient and enables you to use a wide variety of different materials.

The ExAM 255 prints both metal and plastic prototypes without the need for expensive retrofitting. At the same time, the quality of the printed parts is comparable to those printed with conventional FDM and FFF printers.

An automatic material feeder is an essential part of the machine, and each extruder can hold up to one litre of material. This corresponds to approximately 2,8kg PA6GF30 or up to 8.8 kg of stainless steel. Furthermore, the material hopper can be refilled during the printing process.

FAQ about the ExAM 255

How does the printer work?

How does the printer work?

The ExAM 255 is a pellet-based, or granulate-based, material extrusion printer, a so-called pellet MEX printer. The process is similar to filament printers, but considerably faster and uses pellets that are melted in an extruder screw and then extruded.

Can any type of pellets or granulates be used?

Can any type of pellets or granulates be used?

Our ExAM printers are open material systems. Hence, customers can usually use their own existing materials. In the end, the chosen material dictates the minimum nozzle size and the general printability.

Can the machine only print metals or also plastics?

Can the machine only print metals or also plastics?

All our printers are generally able to process all classes of materials. The ExAM 255 is hence able to print plastics, both pure and reinforced, as well as MIM and CIM materials.

What is the difference between the ExAM 255 and the ExAM 510?

What is the difference between the ExAM 255 and the ExAM 510?

The biggest difference between the ExAM 255 and the ExAM 510 is the heating of the build space. Furthermore, the ExAM 510 is considerably faster and can produce larger parts. Due to the indirect heating of the build space, the ExAM 255 is restricted to plastics with a maximum melting point of approximately 320 °C. Please get in touch – we would be happy to give you an initial assessment based on your needs.

What can be said about the expected durability with respect to reinforced plastics?

What can be said about the expected durability with respect to reinforced plastics?

The main element of the ExAM 255 is the extruder, which is constructed in such a manner that all relevant components are hardened. Furthermore, the extruder is designed so that it not only treats the used materials with care, but that the parts that touch these materials are also optimally protected. In the end, the printer can operate for up to 10 000 machine hours before a new extruder, a new hotend or a new extruder screw is needed.