Medicare GmbH

Case Study: socket adapter

Daimler AG, BASF SE

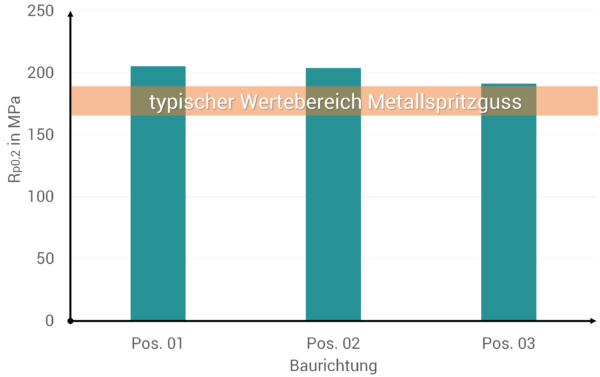

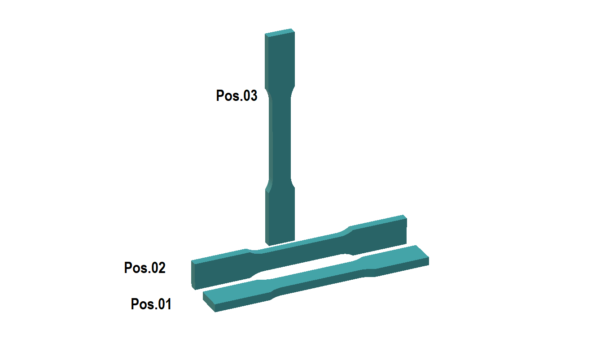

yield strength test Catamold® EVO 316-L

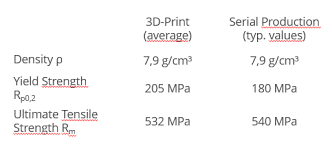

In a collaboration between Daimler AG, BASF SE and AIM3D GmbH, the properties of printed components using the CEM process were investigated in detail.

In these investigations, the mechanical properties of printed parts made from the Catamold® EVO 316-L were compared with the properties of conventional metal injection moulded parts (MIM) made from the same material.

Both the density values after sintering and the determined strengths show that the properties of the 3D printed components are comparable to the properties of series production.

*Results: “Kopp, Alexander: Potenzialermittlung von Additiven Fertigungsverfahren (3D-Drucken) für metallische Fahrzeugstrukturbauteile in der Serienproduktion [expected title], unpublished and not yet completed masterthesis, University of Stuttgart/ Daimler AG, 2018“

Schunk Sintermetalltechnik GmbH

Testing results HK30

The transferability of the material properties of 3D-printed parts is a key factor in supplementing existing production chains. To assess the transferability of 3D-printed parts, a HK 30 from Schunk Sintermetalltechnik was analysed.

HK 30 is a steel for high-temperature applications. The material can be used at temperatures of up to 850°C. A typical area of application is the automotive industry where the material is used for adjusting parts in the turbocharger, for example.

Determination of density DIN EN ISO 3369

AIM3D | 7,54 g/cm³ |

| According to the material data sheet | ≥ 7,50 g/cm3 |

The results of the density determination indicate that the tensile bar, which was printed with the CEM process, meets the requirements according to the material data sheet and can even show better results than the nominal values demanded.

Tensile tests DIN EN ISO 6892-1 A

| Yield strength / proof stress Rp0,2 [MPa] | Tensile strength Rm [MPa] | Elongation at break L0=20mm A [%] | |

AIM3D | 363 | 722 | 26,8 |

| According to the material data sheet | > 350 | > 650 | > 20 |

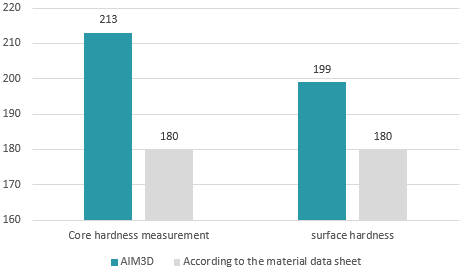

Surface strength / core hardness DIN EN ISO 6507-1

The surface strength and core hardness were also measured according to DIN EN ISO 6507-1. The test values were compared with the material data sheet and achieved an outstanding result. The mean value of the tests carried out were 199 and 213 respectively.

In summary, it can be stated that the tests were carried out successfully. In all tests, the CEM process of AIM3D GmbH can compete with classic manufacturing processes.

All test results were carried out by Schunk Sintermetalltechnik GmbH, test laboratory “Friedrich Eisenkolb”. Report No. 190393 from 22.02.2019