When tool steels are not sufficient, cemented carbides are used. This is often the case when it comes to the production of casting moulds or cutting tools, but also in the chemical industry.

Tungsten carbide is often used in these cases, but it commonly bears the disadvantage of being both very difficult to process and expensive. Very often, it may even be more cost-efficient to erode the part.

With AIM3D’s ExAM machines you can now turn this common disadvantage into your competitive advantage.

AIM3D enables you to print near-net shape components. Depending on your own requirements, you can then either machine the green part before it is sintered or the near-net shape part after it is sintered. This allows you to reduce both your tool costs and machine hours.

Do you have any further questions or are you interested in finding out more about the usable cemented carbides? Please contact us for further information!

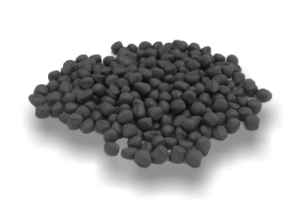

Usable cemented carbide

Wc0,8Co13,5

Wc0,8Co10

FAQs regarding the use of cemented carbide

Can I use commercially available cemented carbide feedstock?

Can I use commercially available cemented carbide feedstock?

Yes, you can. It is not even relevant which binder is used. The ExAM printers support all common debinding methods (thermal, water-soluble, solvable and catalytic).

Does the entire production process of the metal component take place in the printer?

Does the entire production process of the metal component take place in the printer?

No. After the 3D printing process is completed, an additional debinding step is needed to remove the plastic and a sinter oven is needed to seal the component in an additional sintering step. AIM3D‘s open materials system allows you to keep using your already existing debinding and sintering systems.

Can I debind and sinter my 3D printed parts together with other cemented carbide parts?

Can I debind and sinter my 3D printed parts together with other cemented carbide parts?

According to customer feedback, this works very well. Hence, you can save time and money by not having to include separate sintering steps for the parts produced by additive manufacturing.

What are the mechanical properties?

What are the mechanical properties?

In general, the spec sheet values of the used cemented carbide can be achieved, because the mechanical properties of the final component are mainly dependent on the sintering step. This is, in particular, also the case for the z-direction of the component. However, some compromises will usually have to be made in terms of density.